Dehumidifiers

At a Glance

- Reduces power consumption from ice build-up on the evaporators.

- Time wastage is reduced to remove ice in freezers.

- Reduces the chance of food contamination (dripping into the product).

- Reduces product or packaging damage.

- Downtime is reduced while waiting for machinery to dry after washing.

- Reduces the chance of slips and trips from ice or water on the floors.

Why dehumidifiers are required in your refrigeration systems.

As the name suggests, dehumidification removes the water content from the air while lowering the dew point thereby reducing the possibility of condensation. Scantec Refrigeration performs turnkey installation of Swedish manufactured dehumidifiers.

What problems can dehumidification solve for you?

- Build-up of ice in freezers (blast and plate).

- Ice on the floors.

- Wet machinery after cleaning.

- Condensation on the walls, machinery and equipment which can cause mould and dripping contaminated water into the product.

- Corrosion.

- Absorption of moisture by food items, wood, paper and powders (problems with blockages and uneven product).

How does a desiccant dehumidifier work?

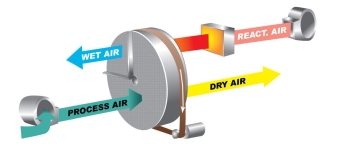

The dehumidifers are of the solid wheel desiccant type and operate using two opposite air streams. The larger humid air volume which is to be dehumidified passes through one sector of a rotor containing absorbent silica gel. Water vapour is retained in the rotor, and dry air exist and enters the space to be dehumidified.

A humistat can be attached to the humidifier in order to measure and control the level of moisture in the space precisely. Moreover, the dehumidifiers can be fitted with PLC (Programmable Logic Controller) unit and contains functions to control the dehumidifier, run-time meters and alarm functions.

Why acquire an industrial dehumidifier from Scantec?

We have many years of experience selecting and installing dehumidifiers along with our ammonia plants. Based on the dimensions of your facility, and precise measurement of physical parameters, we will select the most economical solution to solve the issues with excess humidity you have at your facility.

Dehumidifiers can with benefit be used in combination with air doors from HCR.

If you have a problem with unwanted humidity and would like it solved, please contact us.